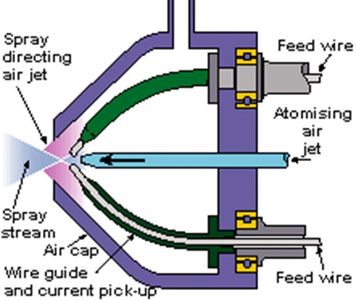

Arc Spray

Of all the thermal spray processes Arc Spraying has the highest deposition rate. A DC electric arc is struck between two wires at the front of the arc spray torch. Compressed air atomizes the molten spray material into fine droplets and propels them towards the prepared surface to be rebuilt. The resulting build-up creates a mechanical bond. There is a wide range of alloys available for arc spraying.

Arc spray (twin wire) can restore damaged and worm components to their original dimensions at a fraction of the cost of expensive replacement spare parts.

Parts such as motor casings, armatures, rotors and end shields can all be successfully repaired. We can effectively restore joint faces and bores in gear boxes, and bearing and seal diameters on a wide range of gears and shafts to the original manufacturing dimensions

Arc Spray is a cost effective method for reclaiming components:

- Large areas are easily coated

- High deposition rate

- Low operating cost

- Fast machining time

- No rework - repeatable coatings

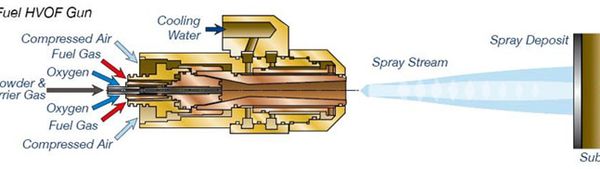

HVOF

HVOF stands for High Velocity Oxygen Fuel. Application rates are lower than arc spray but the density of an HVOF coating and its bond strength are both higher than arc spray.

Advantages

- Provide improved wear, impact and fatigue resistance

- Equal or better corrosion resistance

Applications

- Pump Sleeves

- Wire Drawing Guide

- Extremely hard wear resistant seal diameters

- Mixers

- Mono Pump Screws

- Wet Areas of Pump Volutes and Impellors

- Final Drive Bearing Positions

- Rotary Valve Bodies/Rotors

- Drill Rods

- Turbine Blades

- Wear Rings

- Casting Patterns

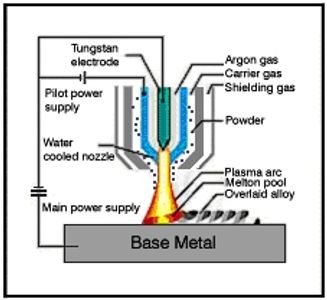

PTA

PTA stands for Plasma Transferred Arc, it uses electricity to create an arc which passes between the PTA torch and the workpiece. This arc creates a molten pool on the surface of the parent material to be overlaid. A metal powder is then fed into the molten pool to create a metallurgical bond with the parent material. There is a wide range of powders available for PTA overlay from stainless alloys to tungsten carbides.

The German designed and constructed PTA system further enhances the range of Thermal Spray services DCL Surface Engineering can extend to customers.

Applications

- Stellite™ overlays for high temperatures

- Valve seats

- Wire Drawing Capstans

- Bearing positions for high compressive loads

- Tungsten Carbide Wear Resistant overlays

- Ball Valves

- Valve Stems

- Sucker Rods

- Replacing Worn Splines

- Guide Rolls

- Forming Dies

- De-watering Screws

Alloy Selection

- Stellite® Alloys

- Tungsten Carbides

- Hastelloy

- Inconel® Alloys

- Aluminium Bronze

- Tool Steels

- NiCrSiB Alloys

- Stainless Steels (300, 400)

Hard Facing

Spray fuse coatings consist of a part being pre-sprayed with a powder. The powder is subsequently fused into the parent material using a heating torch or an oven to keep the heat into the part. This technique is often employed where a component requires a hard facing.

Applications

- Thermowells

- Guide Rolls

- Agitator Impellors

- Compressor Rotor

- Sealing Strips

- Mono Pump Shafts

- Mill Hammers

- Boiler Tubes

- Grinding Hammers

- Wear Rings

- Exhaust Fan Blades

Ceramic Coating

Ceramic coatings are applied to a component through the combustion Powder Flame Spray process. Powder is continually fed into the flame where it is melted by the heat of combustion, propelled towards the prepared workpiece surface and rapidly solidifies to form the coating. Ceramic coatings are used in many industries where an extremely hard, corrosion resistant coating is required.

Advantages

- Ceramic coating reduces wear and tear of the coated components

- Better durability and reliability

Applications

- Seal Diameter

- Thermal Barrier Coatings

- Pump Sleeves

PROCESSES

ARC SPRAY

A DC electric arc is struck between two wires at the front of the arc spray torch. Compressed air atomizes the molten spray material into fine droplets and propels them towards the prepared surface to be rebuilt.

HVOF

Heat is imparted into the very fine powder particles. The molten particles are then propelled at very high velocities to the prepared surface to be rebuilt.

PTA

Electricity is used to create an arc which passes between the PTA torch and the workpiece. This arc creates a molten pool on the surface of the parent material to be overlaid. A metal powder is then fed into the molten pool to create a metallurgical bond with the parent material.

DCL Surface Engineering

27 Malta Street Fairfield East, NSW 2165

Copyright © 2019 DCL Surface Engineering - All Rights Reserved.

Powered by GoDaddy Website Builder